Anodized aluminum CNC machining epitomizes sustainable manufacturing practices, minimizing environmental impact while maximizing resource efficiency. By virtue of its minimal waste generation and judicious resource utilization, the anodization process stands as a paragon of eco-consciousness compared to conventional surface finishing methodologies. Additionally, aluminum's innate recyclability ensures that scrap and waste generated during production can be seamlessly reintegrated into the manufacturing lifecycle, fostering a closed-loop system that champions sustainability. In embracing anodized aluminum CNC machining, manufacturers not only uphold their commitment to environmental stewardship but also deliver superior-quality products imbued with a conscience.

At Strongd, we harness cutting-edge technology to drive anodized aluminum CNC machining to new heights. Our state-of-the-art CNC machining centers, coupled with advanced software solutions, empower us to achieve levels of precision and complexity previously unimaginable. This innovative approach ensures that every component we manufacture meets the stringent demands of modern applications. With continuous investment in research and development, we remain at the forefront of technological advancements in the field of anodized aluminum CNC machining. Our skilled technicians leverage the latest tools and techniques to push the boundaries of what is possible, delivering unmatched quality and performance to our clients.

Beyond its functional benefits, anodized aluminum CNC machining elevates the aesthetics of components to new heights. The anodization process allows for vibrant coloration and sleek finishes, enhancing the visual appeal of the finished product. This fusion of aesthetics and functionality ensures that our CNC-machined anodized aluminum components not only perform flawlessly but also make a lasting impression. With meticulous attention to detail and craftsmanship, we ensure that each component is a testament to both form and function. Our dedication to excellence in both aesthetics and functionality sets us apart as a leader in anodized aluminum CNC machining.

Strongd's commitment to excellence extends to cost-effectiveness. Despite the advanced technology and superior properties involved, our anodized aluminum CNC machining services remain competitively priced. By optimizing our processes and leveraging economies of scale, we deliver exceptional value to our clients without compromising on quality or precision. Our transparent pricing model and efficient production methods ensure that clients receive the highest quality components at the most competitive rates, maximizing their return on investment. With Strongd, clients can expect superior quality, reliability, and performance at a price that fits their budget.

Anodized aluminum CNC machining aligns with Strongd's sustainability ethos. The anodization process minimizes waste and environmental impact compared to traditional surface finishing methods. Additionally, aluminum is highly recyclable, further reducing our ecological footprint. By choosing Strongd for anodized aluminum CNC machining, clients can be confident in their commitment to environmentally responsible manufacturing. Our dedication to sustainability drives us to continually improve our processes and adopt eco-friendly practices throughout our operations. We strive to minimize our environmental impact while maximizing the quality and value we deliver to our clients.

Shenzhen Strongd Model Technology Co., Ltd. is a leading manufacturer founded in 2011, specializing in customized product manufacturing. Our extensive range of services includes Custom Keyboard fabrication, Prototype CNC Machining, CNC Plastic Machining, Metal Parts Milling, ABS Injection Molding, CNC Machining, Aluminum Parts CNC Machining, Injection Molding, Anodized Aluminum CNC, and Rapid Prototype services.

We pride ourselves on our ability to assist customers at every stage of product development, from initial prototyping to small batch production and large-scale manufacturing through molding processes. Utilizing advanced technology and state-of-the-art equipment, we deliver high-quality products that meet the specific needs and requirements of various industries. At Shenzhen Strongd Model, we are committed to providing excellent service and tailored solutions to our customers. With a strong focus on customer satisfaction, we have earned a reputation for reliability and quality within the market.

At Strongd, we excel in providing customized solutions tailored to meet the specific needs and preferences of our clients. Whether it's Custom Keyboards, Prototype CNC Machining, or Injection Molding, we work closely with our customers to ensure that their unique requirements are met with precision and efficiency.

With over a decade of experience in the industry, Strongd boasts a wealth of knowledge and expertise. Our team of skilled professionals is equipped with the technical know-how and practical experience to deliver superior results, ensuring that every project is executed flawlessly from start to finish.

Quality is our top priority at Strongd. We adhere to strict quality control measures throughout the manufacturing process to uphold the highest standards of excellence. Our commitment to quality assurance ensures that every product we produce is of the utmost quality and reliability, earning the trust and confidence of our clients.

Strongd offers a comprehensive range of services, providing our clients with a convenient one-stop solution for all their manufacturing needs. From CNC Machining to Anodized Aluminum CNC and Rapid Prototyping, we have the capabilities to handle every aspect of the production process, allowing our clients to streamline their operations and save time and resources.

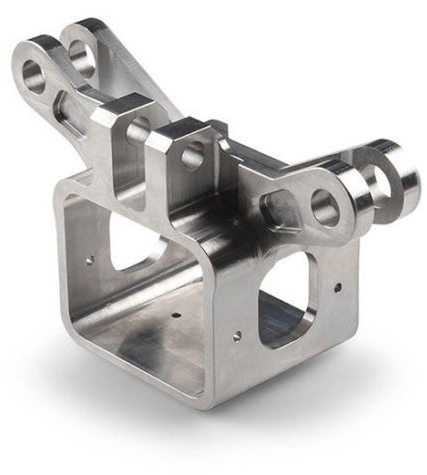

Anodized aluminum CNC machining offers enhanced durability, corrosion resistance, and aesthetic appeal, making it ideal for various applications. The anodization process creates a protective oxide layer on the surface, improving hardness and color options.

Unlike traditional coatings, anodized aluminum integrates with the metal substrate, providing superior durability and scratch resistance. Additionally, it offers a wider range of color options and maintains dimensional stability during machining.

Absolutely. Anodized aluminum CNC machining allows for precise customization, including intricate designs, textures, and finishes. Whether it's decorative or functional features, our machining capabilities ensure precise execution while preserving the benefits of anodization.

Anodized aluminum CNC machining requires careful consideration of tolerances to ensure the desired surface finish and dimensional accuracy. Our experienced team employs advanced machining techniques and precise tooling selection to achieve tight tolerances while maintaining the integrity of the anodized layer.