An inherent advantage of aluminum parts CNC machining lies in its ability to offer a myriad of surface finishes and treatments to enhance the functionality and aesthetics of the components. Following the machining process, aluminum parts can undergo treatments such as anodizing, powder coating, or polishing to improve corrosion resistance, durability, and visual appeal. These surface finishes not only protect the components from environmental elements but also contribute to their overall aesthetic appeal, meeting the stringent standards of various industries.

Our commitment to excellence is reflected in our investment in state-of-the-art CNC machining technology. Equipped with advanced machinery and software, we can tackle the most challenging machining tasks with ease. Our precision machining centers utilize multi-axis capabilities, allowing us to achieve intricate designs and tight tolerances with exceptional accuracy. By leveraging the latest advancements in CNC machining technology, we ensure that our clients receive aluminum parts of the highest quality, consistently meeting their performance and durability requirements.

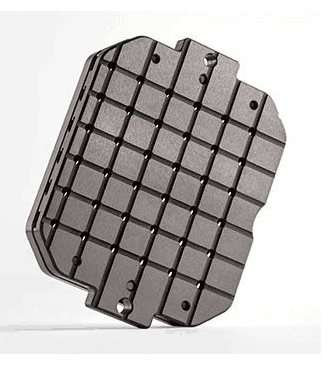

At Strongd, we pride ourselves on delivering precision aluminum parts CNC machining services that meet the highest industry standards. With cutting-edge technology and a team of skilled professionals, we specialize in producing complex aluminum components with unparalleled accuracy and efficiency. Our CNC machining capabilities enable us to handle a wide range of projects, from prototyping to full-scale production, ensuring that each part meets our clients' exact specifications. Whether it's aerospace, automotive, or any other industry, we are committed to delivering top-quality aluminum parts that exceed expectations.

We believe in building collaborative partnerships with our clients based on trust, integrity, and mutual respect. By understanding their unique challenges and goals, we work closely with them to develop innovative solutions and optimize manufacturing processes for maximum efficiency and effectiveness. Our collaborative approach fosters creativity, encourages feedback, and enables us to deliver results that align with our clients' vision and objectives. Whether it's designing a new product, improving existing components, or streamlining production workflows, we are committed to driving mutual success and achieving remarkable outcomes together. At Strongd, we don't just deliver aluminum parts – we forge lasting partnerships that propel businesses forward and ensure long-term success.

Clear communication and responsive support are vital for ensuring a smooth and successful project experience. At Strongd, we prioritize open and transparent communication with our clients, providing regular updates and addressing any concerns or inquiries promptly. From initial project consultation to post-production support, our team is dedicated to providing attentive service and technical guidance every step of the way. We understand the importance of collaboration and partnership in achieving mutual success, and we are committed to being a reliable and supportive partner for all our clients' machining needs.

Shenzhen Strongd Model Technology Co., Ltd. is a leading manufacturer founded in 2011, specializing in customized product manufacturing. Our extensive range of services includes Custom Keyboard fabrication, Prototype CNC Machining, CNC Plastic Machining, Metal Parts Milling, ABS Injection Molding, CNC Machining, Aluminum Parts CNC Machining, Injection Molding, Anodized Aluminum CNC, and Rapid Prototype services.

We pride ourselves on our ability to assist customers at every stage of product development, from initial prototyping to small batch production and large-scale manufacturing through molding processes. Utilizing advanced technology and state-of-the-art equipment, we deliver high-quality products that meet the specific needs and requirements of various industries. At Shenzhen Strongd Model, we are committed to providing excellent service and tailored solutions to our customers. With a strong focus on customer satisfaction, we have earned a reputation for reliability and quality within the market.

At Strongd, we excel in providing customized solutions tailored to meet the specific needs and preferences of our clients. Whether it's Custom Keyboards, Prototype CNC Machining, or Injection Molding, we work closely with our customers to ensure that their unique requirements are met with precision and efficiency.

With over a decade of experience in the industry, Strongd boasts a wealth of knowledge and expertise. Our team of skilled professionals is equipped with the technical know-how and practical experience to deliver superior results, ensuring that every project is executed flawlessly from start to finish.

Quality is our top priority at Strongd. We adhere to strict quality control measures throughout the manufacturing process to uphold the highest standards of excellence. Our commitment to quality assurance ensures that every product we produce is of the utmost quality and reliability, earning the trust and confidence of our clients.

Strongd offers a comprehensive range of services, providing our clients with a convenient one-stop solution for all their manufacturing needs. From CNC Machining to Anodized Aluminum CNC and Rapid Prototyping, we have the capabilities to handle every aspect of the production process, allowing our clients to streamline their operations and save time and resources.

Aluminum parts CNC machining offers exceptional precision, versatility, and cost-effectiveness. It enables the production of complex geometries, tight tolerances, and high-quality surface finishes, making it ideal for a wide range of applications across industries.

Aluminum parts CNC machining utilizes advanced computer-controlled processes to precisely shape aluminum workpieces. This method ensures consistent quality, accuracy, and repeatability in the manufactured components, meeting stringent industry standards reliably.

Aluminum parts CNC machining allows for a variety of surface finishes and treatments, including anodizing, powder coating, and polishing. These processes enhance the appearance, durability, and corrosion resistance of the aluminum components, meeting aesthetic and functional needs effectively.

Aluminum's lightweight nature, excellent machinability, and corrosion resistance make it highly suitable for CNC machining processes. Its thermal conductivity also allows for efficient heat dissipation, making it ideal for applications requiring thermal management.