Aluminum's unique properties, including its lightweight nature, excellent machinability, and corrosion resistance, make it an ideal choice for CNC machining processes. Its low density ensures that machined components remain lightweight without compromising structural integrity, making them suitable for applications where weight reduction is critical. Moreover, aluminum's corrosion resistance minimizes the need for additional protective coatings, simplifying the manufacturing process and reducing overall production costs.

At Strongd, we understand that every project is unique, which is why we offer customized solutions for aluminum parts machining. Whether it's a one-off prototype or a large production run, our team works closely with clients to develop tailored machining strategies that address their specific needs and requirements. From material selection to surface finishing, we take a comprehensive approach to ensure that each aluminum part is manufactured to the highest standards of quality and precision. Our commitment to customization allows us to deliver results that meet and exceed our clients' expectations, no matter the complexity of the project.

We believe in building collaborative partnerships with our clients based on trust, integrity, and mutual respect. By understanding their unique challenges and goals, we work closely with them to develop innovative solutions and optimize manufacturing processes for maximum efficiency and effectiveness. Our collaborative approach fosters creativity, encourages feedback, and enables us to deliver results that align with our clients' vision and objectives. Whether it's designing a new product, improving existing components, or streamlining production workflows, we are committed to driving mutual success and achieving remarkable outcomes together. At Strongd, we don't just deliver aluminum parts – we forge lasting partnerships that propel businesses forward and ensure long-term success.

With years of experience in aluminum machining, we have developed a deep understanding of the material's properties and characteristics. Aluminum is known for its excellent machinability, but its behavior can vary depending on the alloy and temper used. Our team of experts leverages their extensive knowledge to optimize machining processes, select the most suitable tooling, and develop efficient machining strategies that maximize productivity and minimize waste. Whether it's 6061, 7075, or any other aluminum alloy, we have the expertise to deliver precise machining results that meet the stringent requirements of our clients.

Quality is at the core of everything we do at Strongd, and it is ingrained in our machining process from start to finish. We adhere to strict quality control procedures at every stage of production, ensuring that each aluminum part meets the highest standards of accuracy and consistency. Our quality assurance measures encompass material inspection, dimensional checks, and surface finish verification, among others. By maintaining meticulous attention to detail and employing rigorous inspection techniques, we guarantee that every part that leaves our facility is of the utmost quality, meeting or exceeding our clients' expectations.

Shenzhen Strongd Model Technology Co., Ltd. is a leading manufacturer founded in 2011, specializing in customized product manufacturing. Our extensive range of services includes Custom Keyboard fabrication, Prototype CNC Machining, CNC Plastic Machining, Metal Parts Milling, ABS Injection Molding, CNC Machining, Aluminum Parts CNC Machining, Injection Molding, Anodized Aluminum CNC, and Rapid Prototype services.

We pride ourselves on our ability to assist customers at every stage of product development, from initial prototyping to small batch production and large-scale manufacturing through molding processes. Utilizing advanced technology and state-of-the-art equipment, we deliver high-quality products that meet the specific needs and requirements of various industries. At Shenzhen Strongd Model, we are committed to providing excellent service and tailored solutions to our customers. With a strong focus on customer satisfaction, we have earned a reputation for reliability and quality within the market.

At Strongd, we excel in providing customized solutions tailored to meet the specific needs and preferences of our clients. Whether it's Custom Keyboards, Prototype CNC Machining, or Injection Molding, we work closely with our customers to ensure that their unique requirements are met with precision and efficiency.

With over a decade of experience in the industry, Strongd boasts a wealth of knowledge and expertise. Our team of skilled professionals is equipped with the technical know-how and practical experience to deliver superior results, ensuring that every project is executed flawlessly from start to finish.

Quality is our top priority at Strongd. We adhere to strict quality control measures throughout the manufacturing process to uphold the highest standards of excellence. Our commitment to quality assurance ensures that every product we produce is of the utmost quality and reliability, earning the trust and confidence of our clients.

Strongd offers a comprehensive range of services, providing our clients with a convenient one-stop solution for all their manufacturing needs. From CNC Machining to Anodized Aluminum CNC and Rapid Prototyping, we have the capabilities to handle every aspect of the production process, allowing our clients to streamline their operations and save time and resources.

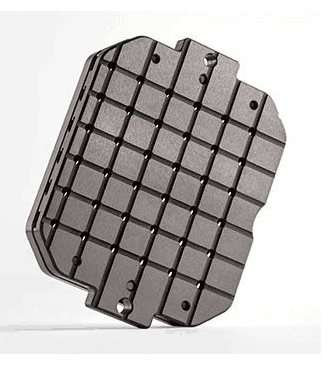

Aluminum parts CNC machining offers exceptional precision, versatility, and cost-effectiveness. It enables the production of complex geometries, tight tolerances, and high-quality surface finishes, making it ideal for a wide range of applications across industries.

Aluminum parts CNC machining utilizes advanced computer-controlled processes to precisely shape aluminum workpieces. This method ensures consistent quality, accuracy, and repeatability in the manufactured components, meeting stringent industry standards reliably.

Aluminum parts CNC machining allows for a variety of surface finishes and treatments, including anodizing, powder coating, and polishing. These processes enhance the appearance, durability, and corrosion resistance of the aluminum components, meeting aesthetic and functional needs effectively.

Aluminum's lightweight nature, excellent machinability, and corrosion resistance make it highly suitable for CNC machining processes. Its thermal conductivity also allows for efficient heat dissipation, making it ideal for applications requiring thermal management.