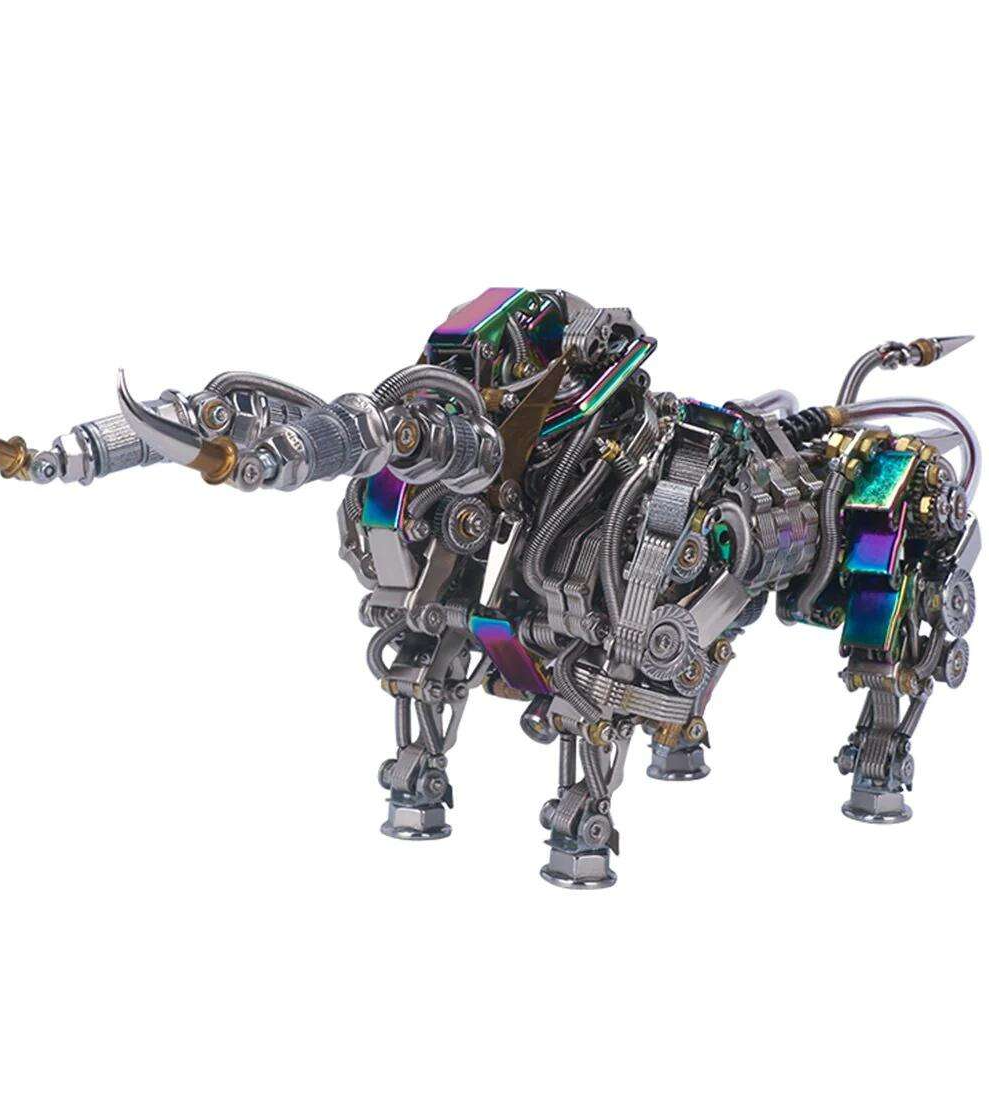

Prototype CNC machining excels in handling complex geometries and intricate designs with ease, thanks to its advanced CNC technology and multi-axis machining capabilities. Whether it's intricate filigree patterns, contoured surfaces, or intricate cavities, prototype CNC machining can precisely reproduce even the most complex geometries with exceptional accuracy. The ability to machine intricate features in a single setup reduces the need for secondary operations, streamlining the prototyping process and minimizing production time. This capability makes prototype CNC machining the ideal choice for prototyping components with demanding geometries and intricate details.

At Strongd, we view ourselves as more than just a service provider—we are your partners in prototyping success. We believe in fostering collaborative partnerships with our clients, working closely with them to understand their unique requirements and objectives. Our team of experienced engineers and technicians offers expert guidance and support throughout the prototyping process, providing valuable insights and recommendations to optimize design and manufacturing efficiency. We understand that effective communication and collaboration are key to delivering successful outcomes, which is why we prioritize open dialogue and transparency in our interactions with clients. With Strongd as your partner, you can expect to receive personalized attention, customized solutions, and unwavering support every step of the way.

Precision engineering is the cornerstone of our prototype CNC machining operations at Strongd. We understand that even the slightest deviation from specifications can have significant repercussions, which is why we leave no stone unturned in ensuring the utmost accuracy and detail in every prototype we produce. Our commitment to precision begins with the selection of the finest CNC machines equipped with advanced capabilities for intricate machining operations. We employ sophisticated CAD/CAM software to meticulously program toolpaths and optimize machining parameters, resulting in prototypes that meet the most stringent tolerances and geometrical requirements. Whether it's a simple part or a complex assembly, our dedication to precision engineering guarantees that each prototype is a true representation of the intended design, instilling confidence in our clients and propelling their projects towards success.

Innovation is at the core of Strongd's DNA, and we are committed to pushing the boundaries of what's possible in prototype CNC machining. We continuously invest in the latest CNC machining technology, software, and talent to stay at the forefront of innovation and excellence. Our relentless pursuit of innovation ensures that we can continue to deliver cutting-edge prototype CNC machining solutions that empower our clients to innovate, iterate, and succeed. With Strongd as your partner, you can trust that we will continue to lead the way in prototype CNC machining, delivering the quality, precision, and reliability you need to bring your ideas to life and shape the future of your industry.

Quality is non-negotiable at Strongd, and our prototype CNC machining operations are held to the highest standards of excellence. We have implemented rigorous quality control measures to ensure that every prototype meets our stringent quality criteria. From material inspection to final part verification, we employ advanced metrology equipment to perform comprehensive dimensional inspections and surface finish analyses. Our meticulous attention to detail and commitment to quality assurance ensure that every prototype produced through our CNC machining process is accurate, reliable, and consistent, meeting the expectations of even the most discerning clients. With Strongd, you can trust that your prototypes will be of the highest quality, enabling you to proceed with confidence in your product development endeavors.

Shenzhen Strongd Model Technology Co., Ltd. is a leading manufacturer founded in 2011, specializing in customized product manufacturing. Our extensive range of services includes Custom Keyboard fabrication, Prototype CNC Machining, CNC Plastic Machining, Metal Parts Milling, ABS Injection Molding, CNC Machining, Aluminum Parts CNC Machining, Injection Molding, Anodized Aluminum CNC, and Rapid Prototype services.

We pride ourselves on our ability to assist customers at every stage of product development, from initial prototyping to small batch production and large-scale manufacturing through molding processes. Utilizing advanced technology and state-of-the-art equipment, we deliver high-quality products that meet the specific needs and requirements of various industries. At Shenzhen Strongd Model, we are committed to providing excellent service and tailored solutions to our customers. With a strong focus on customer satisfaction, we have earned a reputation for reliability and quality within the market.

At Strongd, we excel in providing customized solutions tailored to meet the specific needs and preferences of our clients. Whether it's Custom Keyboards, Prototype CNC Machining, or Injection Molding, we work closely with our customers to ensure that their unique requirements are met with precision and efficiency.

With over a decade of experience in the industry, Strongd boasts a wealth of knowledge and expertise. Our team of skilled professionals is equipped with the technical know-how and practical experience to deliver superior results, ensuring that every project is executed flawlessly from start to finish.

Quality is our top priority at Strongd. We adhere to strict quality control measures throughout the manufacturing process to uphold the highest standards of excellence. Our commitment to quality assurance ensures that every product we produce is of the utmost quality and reliability, earning the trust and confidence of our clients.

Strongd offers a comprehensive range of services, providing our clients with a convenient one-stop solution for all their manufacturing needs. From CNC Machining to Anodized Aluminum CNC and Rapid Prototyping, we have the capabilities to handle every aspect of the production process, allowing our clients to streamline their operations and save time and resources.

Prototype CNC machining can work with a wide range of materials, including metals like aluminum, steel, and titanium, as well as plastics, composites, and even some ceramics.

Prototype CNC machining provides fast turnaround times, allowing for rapid iteration and testing of designs, which accelerates the product development process significantly.

Yes, prototype CNC machining excels in producing prototypes with complex geometries and intricate details, thanks to its advanced CNC technology and precision machining capabilities.

Prototype CNC machining offers cost-effective solutions for low-volume production runs by minimizing setup costs and tooling expenses, making it ideal for producing small batches of prototypes economically.