Quality assurance is a cornerstone of CNC machining service, with stringent measures in place to ensure the highest standards of product quality and reliability. From meticulous material selection and precise tooling calibration to rigorous in-process monitoring and final inspection, every stage of the machining process undergoes thorough scrutiny to identify and rectify any deviations from specifications. Utilizing advanced metrology tools such as coordinate measuring machines (CMMs) and optical scanners, CNC machining service providers verify dimensional accuracy and surface finish, guaranteeing that each component meets or exceeds customer expectations. With a steadfast commitment to quality assurance, CNC machining service delivers confidence and peace of mind in product performance and durability.

At Strongd, our precision CNC machining services are meticulously designed to enhance productivity while ensuring top-notch quality assurance. We understand the critical role that precision plays in the manufacturing process, which is why we employ cutting-edge CNC machinery and advanced techniques. Our dedicated team of skilled technicians and engineers meticulously oversees every step of the machining process to guarantee superior results. By leveraging state-of-the-art technology and industry best practices, we deliver machined parts with unparalleled precision and efficiency. Whether it's intricate components for aerospace applications or precision parts for medical devices, our CNC machining services are tailored to meet the exact specifications and requirements of our clients, ensuring enhanced productivity and unwavering quality assurance.

Quality assurance is at the core of our CNC machining service at Strongd. We uphold the highest standards of quality and reliability throughout the machining process to ensure consistent performance and durability of our products. Our rigorous quality control processes encompass comprehensive inspections, dimensional accuracy checks, and functional testing to guarantee adherence to strict quality standards. From material procurement to final inspection, we prioritize quality at every stage to deliver machined parts that meet or exceed our clients' expectations. With our unwavering commitment to quality assurance, our clients can trust in the reliability and performance of our products, ensuring their peace of mind and satisfaction.

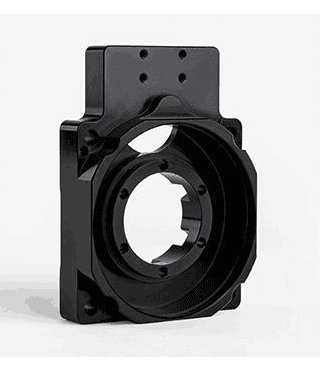

Strongd takes pride in offering a comprehensive CNC machining service that caters to a diverse range of industries and applications. With our extensive experience and expertise, we serve sectors including aerospace, automotive, medical, electronics, and more. Our versatile capabilities enable us to manufacture complex components and parts for various applications, from prototyping to full-scale production. We understand the unique challenges and requirements of each industry sector, and we tailor our CNC machining services accordingly. Whether it's rapid prototyping for the automotive industry or precision machining for medical implants, we deliver high-quality solutions that exceed expectations. Our commitment to excellence and versatility ensures that we can meet the evolving needs of our clients across diverse industries and applications.

Strongd is committed to providing a responsive CNC machining service that ensures timely deliveries and operational efficiency for our clients. We understand the importance of meeting deadlines and schedules, which is why we prioritize responsiveness and agility in our manufacturing processes. With streamlined production workflows and efficient project management practices, we optimize lead times and minimize turnaround times without compromising on quality. Our flexible manufacturing capabilities enable us to accommodate urgent orders and respond quickly to changing demands, ensuring that our clients receive their machined parts promptly. By delivering on time, every time, we help our clients maintain operational efficiency and meet their business objectives effectively.

Shenzhen Strongd Model Technology Co., Ltd. is a leading manufacturer founded in 2011, specializing in customized product manufacturing. Our extensive range of services includes Custom Keyboard fabrication, Prototype CNC Machining, CNC Plastic Machining, Metal Parts Milling, ABS Injection Molding, CNC Machining, Aluminum Parts CNC Machining, Injection Molding, Anodized Aluminum CNC, and Rapid Prototype services.

We pride ourselves on our ability to assist customers at every stage of product development, from initial prototyping to small batch production and large-scale manufacturing through molding processes. Utilizing advanced technology and state-of-the-art equipment, we deliver high-quality products that meet the specific needs and requirements of various industries. At Shenzhen Strongd Model, we are committed to providing excellent service and tailored solutions to our customers. With a strong focus on customer satisfaction, we have earned a reputation for reliability and quality within the market.

At Strongd, we excel in providing customized solutions tailored to meet the specific needs and preferences of our clients. Whether it's Custom Keyboards, Prototype CNC Machining, or Injection Molding, we work closely with our customers to ensure that their unique requirements are met with precision and efficiency.

With over a decade of experience in the industry, Strongd boasts a wealth of knowledge and expertise. Our team of skilled professionals is equipped with the technical know-how and practical experience to deliver superior results, ensuring that every project is executed flawlessly from start to finish.

Quality is our top priority at Strongd. We adhere to strict quality control measures throughout the manufacturing process to uphold the highest standards of excellence. Our commitment to quality assurance ensures that every product we produce is of the utmost quality and reliability, earning the trust and confidence of our clients.

Strongd offers a comprehensive range of services, providing our clients with a convenient one-stop solution for all their manufacturing needs. From CNC Machining to Anodized Aluminum CNC and Rapid Prototyping, we have the capabilities to handle every aspect of the production process, allowing our clients to streamline their operations and save time and resources.

CNC machining service offers precise and efficient manufacturing capabilities, ensuring accuracy and consistency in producing custom parts. It enables rapid prototyping, cost-effective production, and the ability to work with a wide range of materials, making it a versatile solution for various industries.

CNC machining service utilizes computer-controlled machines and precise programming to execute machining operations with utmost accuracy. This ensures consistent quality and dimensional accuracy in each component produced, meeting stringent industry standards and specifications.

Absolutely. CNC machining service excels in handling complex geometries and tight tolerances, thanks to its advanced capabilities and precision tools. Whether it's intricate shapes or demanding specifications, CNC machining delivers high-quality results with exceptional precision.

CNC machining service is compatible with a wide range of materials, including metals, plastics, and composites. This versatility allows for the production of components with diverse properties and characteristics to meet specific application requirements.