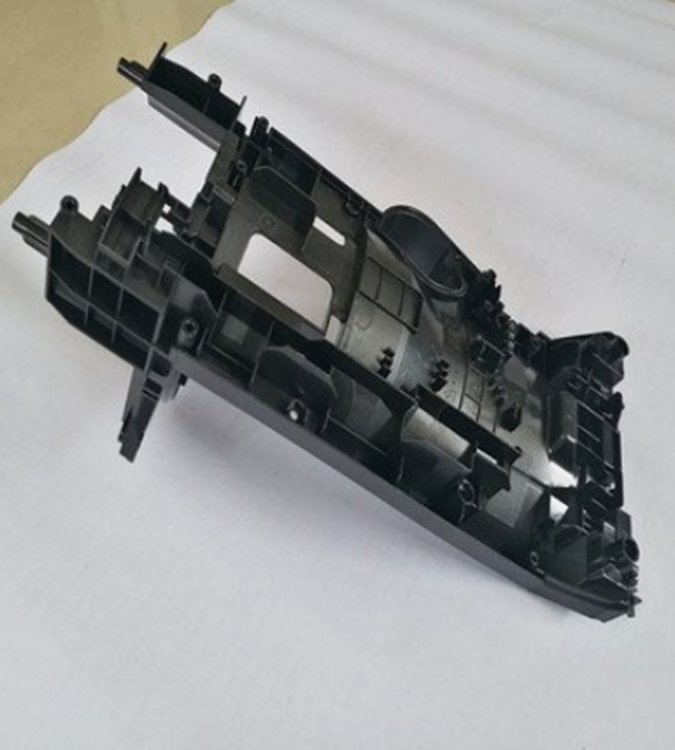

Injection molding offers unparalleled design flexibility, allowing for the creation of parts with intricate geometries and complex features that would be challenging or impossible to achieve with other manufacturing processes. With the ability to mold undercuts, thin walls, and intricate details, injection molding empowers designers to unleash their creativity and push the boundaries of product design. Moreover, features such as ribs, bosses, and snap fits can be incorporated directly into the mold design, eliminating the need for secondary assembly processes and reducing overall production costs. Whether it's intricate cosmetic details or functional components with complex geometry, injection molding enables the realization of virtually any design concept with precision and consistency.

Strongd distinguishes itself through its bespoke injection molding services, tailored to meet the unique needs and specifications of our esteemed clientele. From conceptualization to fruition, our team collaborates closely with clients to discern their specific challenges and devise customized solutions that address their requirements. Whether optimizing part designs for injection molding, selecting appropriate materials, or maximizing production efficiency, we remain steadfast in our commitment to ensuring client satisfaction. With Strongd's customer-centric approach, clients can rest assured that they will receive injection molded solutions of unparalleled quality and precision, meticulously crafted to meet their exact specifications.

At Strongd, our injection molding process epitomizes precision and efficiency, setting industry benchmarks for quality and productivity. Our journey begins with meticulous design and mold preparation, where our team of seasoned engineers harnesses cutting-edge software and technology to craft molds with exacting specifications and intricate details. Subsequently, our state-of-the-art injection molding machines, guided by stringent parameters, inject molten plastic material into the mold cavity with precision and consistency. This results in each part being formed with immaculate accuracy, meeting the most stringent quality standards. Our commitment to precision and efficiency underscores Strongd as a reliable partner for injection molding solutions, delivering unparalleled results with every project.

Strongd's reputation for reliability and consistency in injection molding is built upon a foundation of unparalleled expertise and experience. With decades of industry knowledge, we have honed our processes and techniques to deliver injection molded parts of exceptional quality consistently. Our cutting-edge facilities, coupled with our skilled workforce and stringent quality control protocols, ensure that each part meets the highest standards of performance and durability. Whether producing small-scale prototypes or large production runs, clients can rely on Strongd for injection molding solutions characterized by unwavering reliability and unmatched consistency.

Strongd prides itself on its extensive range of injection molding capabilities, capable of addressing a myriad of customer needs and specifications. Our injection molding machines boast versatility, accommodating various materials such as thermoplastics, thermosetting polymers, elastomers, and engineering plastics. Moreover, we possess the capacity to produce parts in a multitude of sizes and complexities, from intricate components to substantial structural parts. Be it rapid prototyping, low-volume production, or high-volume manufacturing, Strongd's flexibility and expertise empower us to provide tailored injection molding solutions that precisely align with our clients' requirements.

Shenzhen Strongd Model Technology Co., Ltd. is a leading manufacturer founded in 2011, specializing in customized product manufacturing. Our extensive range of services includes Custom Keyboard fabrication, Prototype CNC Machining, CNC Plastic Machining, Metal Parts Milling, ABS Injection Molding, CNC Machining, Aluminum Parts CNC Machining, Injection Molding, Anodized Aluminum CNC, and Rapid Prototype services.

We pride ourselves on our ability to assist customers at every stage of product development, from initial prototyping to small batch production and large-scale manufacturing through molding processes. Utilizing advanced technology and state-of-the-art equipment, we deliver high-quality products that meet the specific needs and requirements of various industries. At Shenzhen Strongd Model, we are committed to providing excellent service and tailored solutions to our customers. With a strong focus on customer satisfaction, we have earned a reputation for reliability and quality within the market.

At Strongd, we excel in providing customized solutions tailored to meet the specific needs and preferences of our clients. Whether it's Custom Keyboards, Prototype CNC Machining, or Injection Molding, we work closely with our customers to ensure that their unique requirements are met with precision and efficiency.

With over a decade of experience in the industry, Strongd boasts a wealth of knowledge and expertise. Our team of skilled professionals is equipped with the technical know-how and practical experience to deliver superior results, ensuring that every project is executed flawlessly from start to finish.

Quality is our top priority at Strongd. We adhere to strict quality control measures throughout the manufacturing process to uphold the highest standards of excellence. Our commitment to quality assurance ensures that every product we produce is of the utmost quality and reliability, earning the trust and confidence of our clients.

Strongd offers a comprehensive range of services, providing our clients with a convenient one-stop solution for all their manufacturing needs. From CNC Machining to Anodized Aluminum CNC and Rapid Prototyping, we have the capabilities to handle every aspect of the production process, allowing our clients to streamline their operations and save time and resources.

Injection molding offers advantages such as high production efficiency, precise dimensional control, versatility in design, and the ability to produce complex geometries with tight tolerances.

Injection molding maintains consistent part quality through precise control of process parameters, such as temperature, pressure, and injection speed, ensuring uniformity across production batches.

Injection molding accommodates a wide range of materials, including thermoplastics, thermosetting polymers, elastomers, and engineering plastics, providing versatility for various applications.

Yes, injection molding is well-suited for large-scale production runs, offering high efficiency, fast cycle times, and the capability to produce thousands to millions of parts with consistent quality.