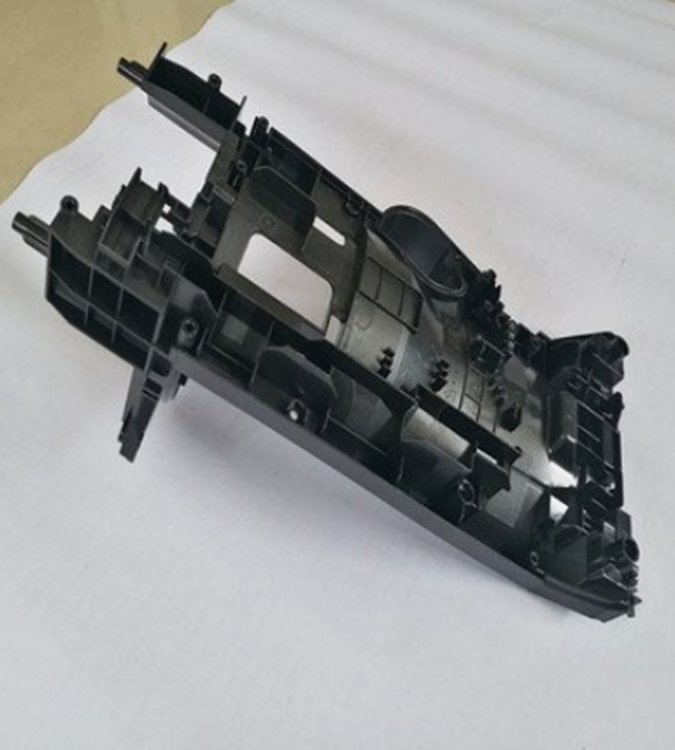

One of the key strengths of injection molding lies in its versatility in material selection, accommodating a wide range of thermoplastic and thermosetting polymers. From commodity plastics like polyethylene and polypropylene to engineering plastics like ABS, PC, and nylon, injection molding can process a diverse array of materials to suit various application requirements. Additionally, specialty polymers and biodegradable materials can also be utilized, providing further flexibility in material selection. This versatility enables manufacturers to choose the most suitable material for their specific needs, balancing properties such as strength, durability, heat resistance, and chemical compatibility to achieve optimal performance in the final product.

Strongd prides itself on its extensive range of injection molding capabilities, capable of addressing a myriad of customer needs and specifications. Our injection molding machines boast versatility, accommodating various materials such as thermoplastics, thermosetting polymers, elastomers, and engineering plastics. Moreover, we possess the capacity to produce parts in a multitude of sizes and complexities, from intricate components to substantial structural parts. Be it rapid prototyping, low-volume production, or high-volume manufacturing, Strongd's flexibility and expertise empower us to provide tailored injection molding solutions that precisely align with our clients' requirements.

Strongd's reputation for reliability and consistency in injection molding is built upon a foundation of unparalleled expertise and experience. With decades of industry knowledge, we have honed our processes and techniques to deliver injection molded parts of exceptional quality consistently. Our cutting-edge facilities, coupled with our skilled workforce and stringent quality control protocols, ensure that each part meets the highest standards of performance and durability. Whether producing small-scale prototypes or large production runs, clients can rely on Strongd for injection molding solutions characterized by unwavering reliability and unmatched consistency.

At Strongd, quality assurance is paramount in our injection molding operations, underscoring our unwavering dedication to delivering superior products. Throughout the production process, rigorous quality control measures are implemented, ensuring that each part adheres to the highest standards of excellence. From meticulous material selection to meticulous mold preparation, injection molding, and final inspection, our team of adept technicians and engineers meticulously scrutinize each phase to detect and rectify any potential deviations. This steadfast commitment to quality assurance guarantees that every injection molded part bearing the Strongd insignia is synonymous with reliability, durability, and impeccable performance.

Strongd remains steadfast in its pursuit of excellence, continuously striving to enhance our injection molding capabilities and stay abreast of industry trends. We invest significantly in ongoing training and development for our team members, ensuring they remain at the forefront of technological advancements and best practices in injection molding. Furthermore, we routinely evaluate and optimize our processes to enhance efficiency, reduce lead times, and minimize costs. By fostering a culture of continuous improvement, Strongd positions itself as a leader in innovation and excellence in injection molding, delivering superior products and services that exceed client expectations consistently.

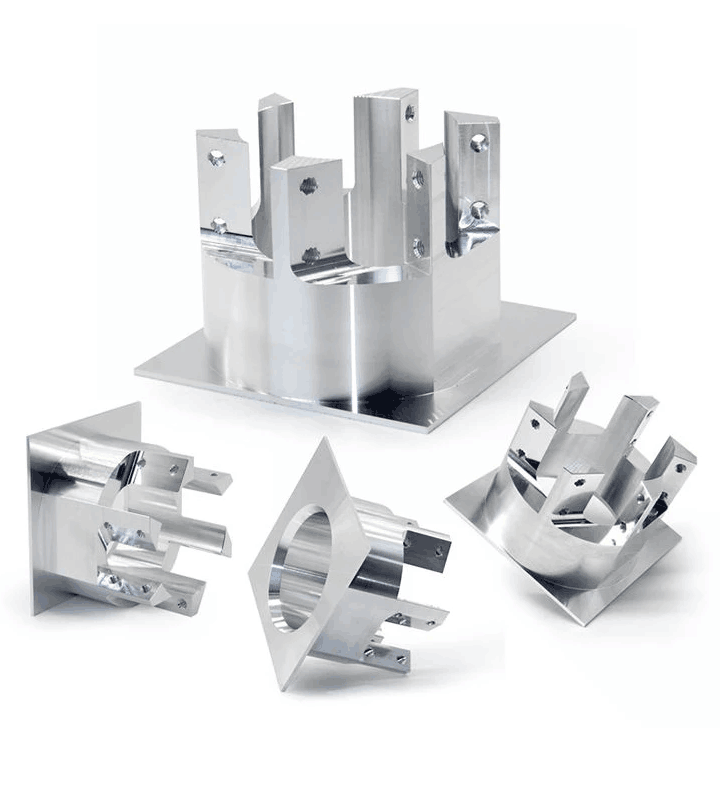

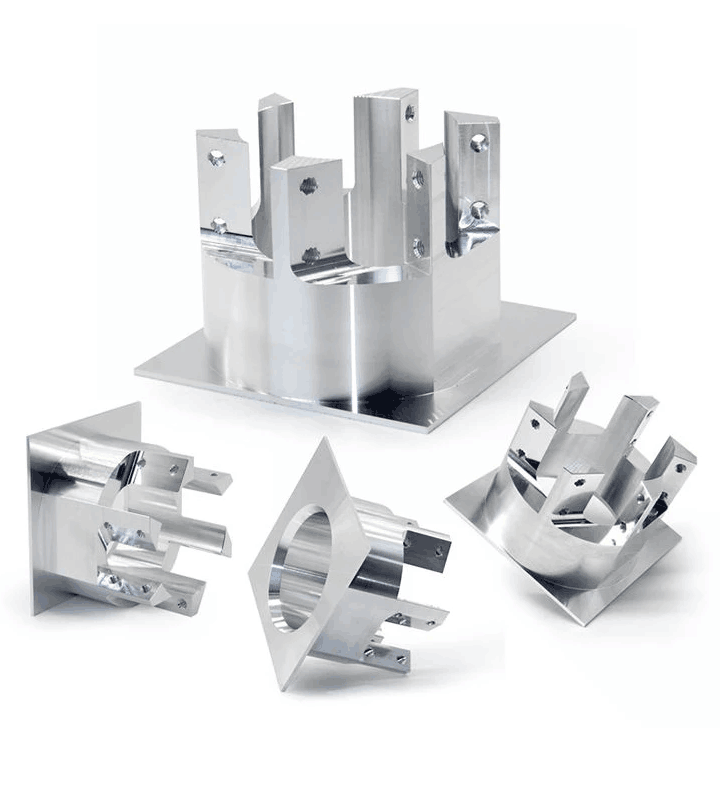

Shenzhen Strongd Model Technology Co., Ltd. is a leading manufacturer founded in 2011, specializing in customized product manufacturing. Our extensive range of services includes Custom Keyboard fabrication, Prototype CNC Machining, CNC Plastic Machining, Metal Parts Milling, ABS Injection Molding, CNC Machining, Aluminum Parts CNC Machining, Injection Molding, Anodized Aluminum CNC, and Rapid Prototype services.

We pride ourselves on our ability to assist customers at every stage of product development, from initial prototyping to small batch production and large-scale manufacturing through molding processes. Utilizing advanced technology and state-of-the-art equipment, we deliver high-quality products that meet the specific needs and requirements of various industries. At Shenzhen Strongd Model, we are committed to providing excellent service and tailored solutions to our customers. With a strong focus on customer satisfaction, we have earned a reputation for reliability and quality within the market.

At Strongd, we excel in providing customized solutions tailored to meet the specific needs and preferences of our clients. Whether it's Custom Keyboards, Prototype CNC Machining, or Injection Molding, we work closely with our customers to ensure that their unique requirements are met with precision and efficiency.

With over a decade of experience in the industry, Strongd boasts a wealth of knowledge and expertise. Our team of skilled professionals is equipped with the technical know-how and practical experience to deliver superior results, ensuring that every project is executed flawlessly from start to finish.

Quality is our top priority at Strongd. We adhere to strict quality control measures throughout the manufacturing process to uphold the highest standards of excellence. Our commitment to quality assurance ensures that every product we produce is of the utmost quality and reliability, earning the trust and confidence of our clients.

Strongd offers a comprehensive range of services, providing our clients with a convenient one-stop solution for all their manufacturing needs. From CNC Machining to Anodized Aluminum CNC and Rapid Prototyping, we have the capabilities to handle every aspect of the production process, allowing our clients to streamline their operations and save time and resources.

Injection molding offers advantages such as high production efficiency, precise dimensional control, versatility in design, and the ability to produce complex geometries with tight tolerances.

Injection molding maintains consistent part quality through precise control of process parameters, such as temperature, pressure, and injection speed, ensuring uniformity across production batches.

Injection molding accommodates a wide range of materials, including thermoplastics, thermosetting polymers, elastomers, and engineering plastics, providing versatility for various applications.

Yes, injection molding is well-suited for large-scale production runs, offering high efficiency, fast cycle times, and the capability to produce thousands to millions of parts with consistent quality.