- Overview

- Parameter

- Inquiry

- Related Products

Item | CNC machining service parts |

Material | Plastic—ABS, PC, PMMA, POM, PA (NYLON), PP, PBT, etc. Metal—Aluminum, Copper, Rubber, Stainless Steel, Sheet Metal, Alloy |

Available Service | 1. Industrial Design 2. CNC Rapid Prototyping 3. SLS/SLA/3D Printing Prototype Service 4. High Precision CNC Machining 5. Silicone Mold (Vacuum Casting) & Rapid Tooling |

MOQ | 1 piece |

Surface Treatment | Painting, Polish, Silk-sreen Printing, Anodized, Electronic Plated, Sandblasted, Translucent Surface, Brush, Bending, etc |

Available Drawing Format | 2D Format-- .dwg/.cdr/.pdf/.ai 3D Format-- .igs/.stp/.step/.sld/.prt/X_T |

The fields we serve | 1. Electronic Digital 2. Medical Devices 3. Telecommunications 4. Auto Parts 5. Household Appliance 6. Kitchenwares |

Our Advantage | 1. Good quality and reasonable price. 2. Shot lead time. 3. Advanced technology and equipment. 4. Responsible for any quality problems from us. |

What can Shenzhen Strongd Model Do?

1. CNC Machining Prototype (Both plastic and metal materials)

2. Rapid Prototyping Service

3. Plastic Injection Molding Service

4. Die Casting Services

5. 3D Printing/ Aluminum Profile/ Sheet Metal Machining Services

Welcome to contact for a trial order!

Where we display the products we've made under the authorization of our clients

Available materials : Aluminum, Stainless steel, Iron, copper, Brass, Plastic etc.

Drawing Format: step, x_t, igs, stp, prt, sldprt.

Tolerance : +/- 0.01 mm ( metal parts) +/- 0.05 mm (Plastic parts)

Step 1 - Make master patterns using SLA/ SLS base on 3d drawing.

Step 2 - Pour liquid silicone around the master pattern in a casting box

Step 3 - Cure it in an over for 16 hours ( vacuum process -bake-cool)

Step 4 - Cut the mold open and remove the master part

Step 5 - Empty cavity in the exact shape as the original

Step 6 - Pour the casting resins and make exact copies of original

A: We are a factory.

Q: What are your terms of payment?

A: 50%deposit before arranging production, the balance should be paid before delivery.

Q: How soon can I get a reply after sending the inquiry?

A: All inquiries would be replied to within 2 hours, except sleeping time in China; and our cell phones are standing by any calls at any time.

Q: What should I provide for price inquiry?

A: The 3d drawing in STP/ STEP/ IGS/ X_T/ SLD format, with information about the material, quantity, surface treatment, tolerance, and requirements.

Q:How can I get a prototype if I don't have a drawing?

A: If you don't have any drawings, you can send us your samples, we'll scan them and make the drawing first, then make a prototype for you.

Q: What is your MOQ ( minimum order quantity)?

A: The MOQ is 1 piece for rapid prototyping, you are welcome to send us a trial order to test our quality and services.

Q: What is your payment term?

A: CIF, EXW or FOB Shenzhen, paid by T/T, Paypal, Trade Assurance Order.

Other attributes

Place of Origin | Guangdong,China |

Type | Broaching, DRILLING, Laser Machining, Milling,Other Machining Services, Turning, Wire EDM,Rapid Prototyping |

Micro Machining or Not | Micro Machining |

Model Number | SJD24353 |

Brand Name | StrongD |

Product name | Custom Keyboard |

Surface treatment | Anodizedcolor, Plating, Powder coating,Anodized |

Service | Customized OEM |

Color | Customized Color |

Drawing Format | STP.STEP.IGS.PRT.X_T |

MOQ | 1 Piece |

Tolerance | 0.05-0.1mma |

Delivery Time | 5 days |

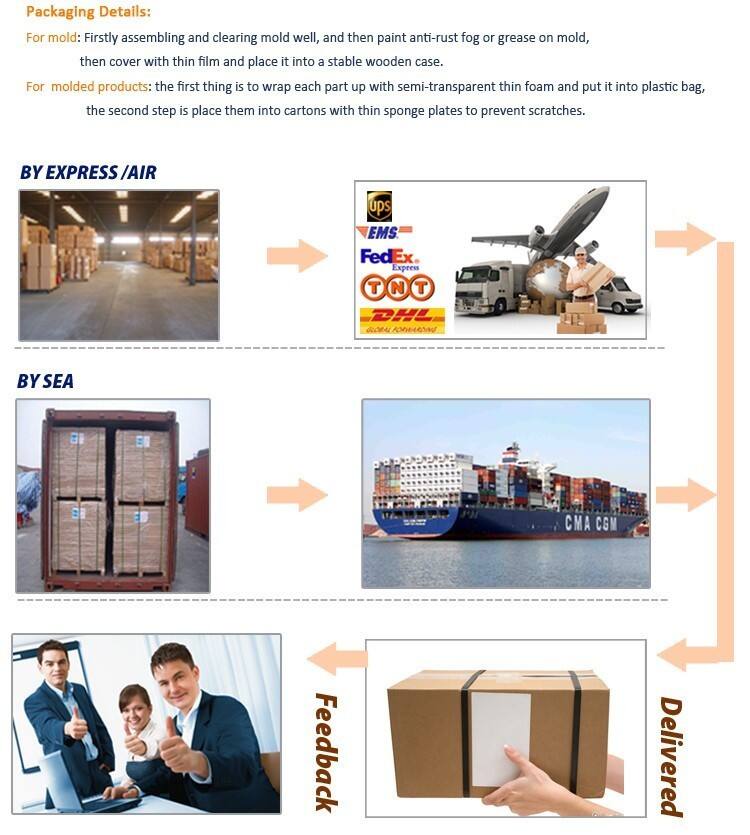

Packing | Carton+ Wooden Box |

Lead time

Quantity(pieces) | 1-500 | >500 |

Lead time (days) | 10 | To be negotiated |

Samples

Maximum order quantity:10 piece

Sample price: US$5.00/piece

Customization

Products Customization

Min.order: 1

Customizedlogo

Min.order: 1

Customized packaging

Min.order: 500

Graphic customization

Min.order: 1

For more customization details, message supplier

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

IS

IS

BN

BN

LA

LA