CNC Manufacturing Custom Split Aluminium Metal Case CNC Machining Mechanical Gaming Keyboard Service

- Overview

- Parameter

- Inquiry

- Related Products

Item | CNC Manufacturing Custom Split Aluminium Metal Case CNC Machining Mechanical Gaming Keyboard Service |

Materials available | Plastic ---ABS, PC, PMMA, PA(Nylon), Rubber, Silicone.etc.(basically all the common material for machining work) Metal---Aluminum(alloy), Copper, Brass, Stainless Steel, Sheet Metal. |

Color | Any color/custom(please share Pantone code or color plate) |

surface treatment | Paint, polish, silk-screen printing, anodize, electronic plating, sandblast, translucent surface, brush, rubber oil, ect.( from machining/production to finish--one stop service) |

Available Format | Auto CAD/.IGS/.STP/.X_T/.PRT/.STEP/.STL, Cero, UG |

The fields we serve | Electronic digital/Consumers goods Medical devices Telecommunications Auto parts Household appliances Kitchenwares |

Available Service | Strongd could help you with design work Industrial designCNC rapid prototyping SLA/SLS 3D rapid prototype service High-precision CNC machining Silicone mold(vacuum casting)& rapid tooling Injection moulding for mass production work (plastic parts) die casting for mass production work(metal parts: A380, Magnesium material, custom material available) |

Our advantages | 1. Strongd could help with designing ideas 2. Good quality and Reasonable price 3. Fast lead time 4. Advanced technology and equipment. 5. Responsible for any quality problems from us. |

Anodizing Aluminum

Hard Anodizing

Powder Coating

Chroming

Polishing

Brushing ect.

Conventional Material

AL 6061 AL 6062 AL 6063

AL 7075

AL 5052

Brass

Bronze

Cooper

Surface Finish

Plating

Brushing

4140 / 4130 / 4340 A2 Tool Steel

SUS 304SUS303 SS 316 440C Stainless Steel

Surface Finish

Polishing

Powder Coating

Galvanized

Chroming

Electropolishing

Plating

Blackening

Shenzhen Strongd Model Technologyis a marketing leader in the industry of Design-Prototypes-Mold-Assembly-Shipment. Including the following services:Product Design-Prototype Production-Mass Production.

We cherish our client's ideas most, we aim to ensure that customers always get the best quality products, and services and deliver all the prototyping requirements in time, helping them to develop new products and launch them into the marketplace ahead of their competitors to win more profit.

Strong would try its best to support your great ideas!

Post /Surface Treatment Available

The procedure: our craftsmen would polish the parts smoothly-- anodizing work/ electroplating work--inspection work

Polish process

Painting process

Electroplating

Anodize

Laser Engraving

Aluminum parts | Stainless Steel parts | Steel | Plastic |

Polishing | Polishing | Polishing | Polishing |

Clear Anodized | Passivating | Oxide black | Chrome |

Color Anodized | Bead blast | Nickel plating | Electroplate |

Bead blast | laser engraving | Chrome plating | Brushing (Acylic) |

Brushing | Heat treatment | Carburized | Laser engraving |

Chrome | Powder coat | Heat treatment | |

Powder coat | Powder coat | ||

Electroplate |

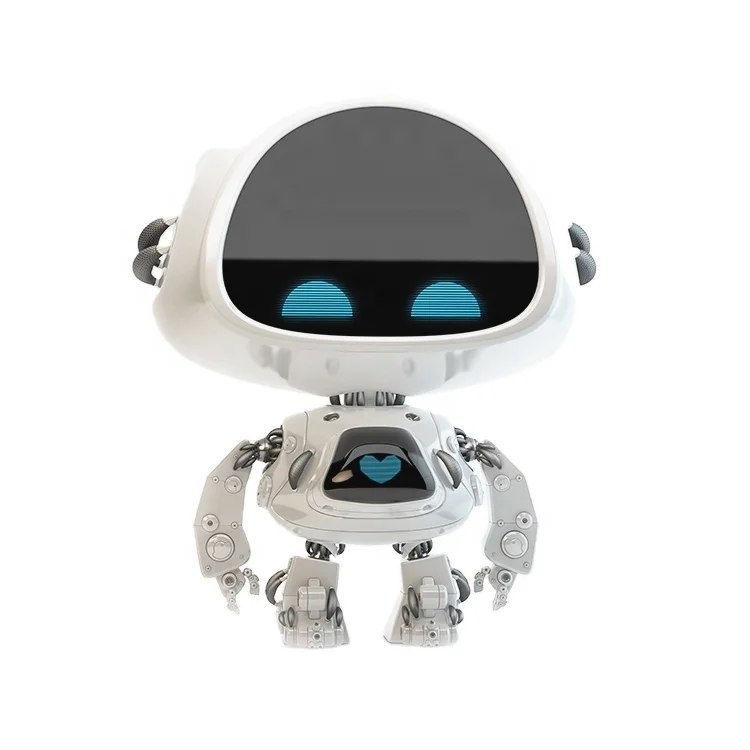

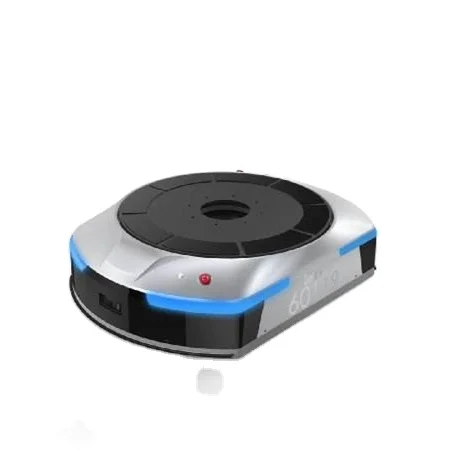

Where we display the products we've made under the authorization of our clients

Available materials: Aluminum, Stainless steel, Iron, copper, Brass, Plastic etc...

Drawing Format: step, x_t, igs, stp, prt, sldprt.

Tolerance : +/- 0.01 mm ( metal parts) +/- 0.05 mm (Plastic parts)

Step 1 - Make master patterns using SLA/ SLS based on 3d drawing.

Step 2 - Pour liquid silicone around the master pattern in a casting box

Step 3 - Cure it in an oven for 16 hours ( vacuum process -bake-cool)

Step 4 - Cut the mould open and remove the master part

Step 5 - Empty cavity in the exact shape as the original

Step 6 - Pour the casting resins and make exact copies of the original

A: Generally it is 3-5 days, it should be according to quantity.

Q: What are your terms of payment?

A: 50%deposit before arranging production, the balance should be paid before delivery.

Q: How will you ship the products to me?

A: We will make the best plan to ship the products as per their size and material. We generallyuse DHL / FedEx / UPS/ EMS.

Q: Can I know how my products go without visiting your company?

A: We will offer a detailed production schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q: If you make poor-quality goods, will you refund our funds?

A: As a matter of fact, we won't take a chance to make poor quality products. Meanwhile, we manufacture good quality products until we reach your satisfaction.

Other attributes

Place of Origin | Guangdong,China |

Type | Broaching, DRILLING, Laser Machining, Milling,Other Machining Services, Turning, Wire EDM,Rapid Prototyping |

Micro Machining or Not | Micro Machining |

Model Number | SJD24353 |

Brand Name | StrongD |

Product name | Custom Keyboard |

Surface treatment | Anodizedcolor, Plating, Powder coating,Anodized |

Service | Customized OEM |

Color | Customized Color |

Drawing Format | STP.STEP.IGS.PRT.X_T |

MOQ | 1 Piece |

Tolerance | 0.05-0.1mma |

Delivery Time | 5 days |

Packing | Carton+ Wooden Box |

Lead time

Quantity(pieces) | 1-500 | >500 |

Lead time (days) | 10 | To be negotiated |

Samples

Maximum order quantity:10 piece

Sample price: US$5.00/piece

Customization

Products Customization

Min.order: 1

Customizedlogo

Min.order: 1

Customized packaging

Min.order: 500

Graphic customization

Min.order: 1

For more customization details, message supplier

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

SV

SV

TL

TL

IW

IW

ID

ID

LT

LT

SR

SR

SK

SK

SL

SL

UK

UK

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

FA

FA

AF

AF

MS

MS

IS

IS

BN

BN

LA

LA